As you can see, calculating your predetermined overhead rate is a crucial first step in pricing your products correctly. Detailed analysis of predetermined overhead rates helps businesses identify the activities or factors that drive overhead costs, enabling targeted cost-reduction measures. Predetermined overhead rates are used to assign overhead costs to products or services, enabling accurate product costing and pricing. To calculate a predetermined overhead rate for mixed costs, the fixed and variable portions must be separated.

Methods of Applying Predetermined Overhead Rates

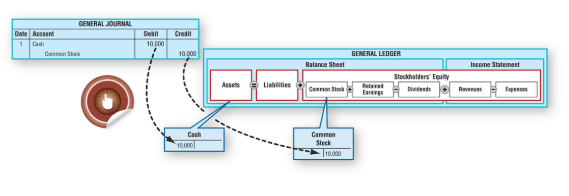

Next, we look at how we correct our records when the actual and our applied (or estimated) overhead do not match (which they almost never match!). The Predetermined Overhead Rate Calculator helps businesses allocate manufacturing overhead costs to products or jobs based on a consistent rate. The company needs to use predetermined overhead rate to calculate the cost of goods sold and inventory balance. Cost of goods sold equal to the sales quantity multiply by the total cost per unit which include the overhead cost. We also use the same rate to calculate the inventory balance at the end of accounitng period. However, the variance between actual overhead and estimated will be reconciled and adjust to the financial statement.

Activity Base Selection

- As you have learned, the overhead needs to be allocated to the manufactured product in a systematic and rational manner.

- For example, we can use labor hours worked, and for calculating overhead for the store department, we can use the quantity of material to be used.

- Common examples include machine hours, direct labor hours, or direct materials costs.

- Following are some of the advantages of using a predetermined overhead rate.

The computation of the overhead cost per unit for all of the products is shown in Figure 6.4. The overhead rate is calculated by dividing total overhead costs by an appropriate allocation measure such as direct labor hours. The predetermined overhead rate is an estimated rate used to assign manufacturing overhead to products or jobs before actual costs are known. It spreads overhead evenly across production, helping managers avoid monthly or seasonal swings in utilities, maintenance, or indirect labor. The most common types of activity used to calculate a POHR are direct labor hours, machine hours, and units produced. For example, direct labor hours or machine hours can be used as the measure of activity.

- Calculating the predetermined overhead rate is a crucial step in cost accounting, allowing businesses to accurately allocate overhead costs to their products or services.

- In general, management teams will divide expenses between these two categories because they provide broader insight into an accurate product cost and the manufacturing of a product.

- In some cases, it may be necessary to use multiple overhead rates for different departments or activities within a company.

- However, modern absorption requires the use of multiple bases to enhance the accuracy of the process.

- The activity driver, also known as the allocation base, is the factor used to assign overhead costs to products.

Overhead Cost Allocation

Also, profits will be affected when sales and production decisions are based on an inaccurate overhead rate. One of the advantages of predetermined overhead rate is that businesses can use it to help with closing their books more quickly. This is because using this rate allows them to avoid compiling actual overhead costs as part predetermined overhead rate formula of their closing process.

How to find predetermined overhead rate: Example 1

- If you’re running several warehouses, calculate separate rates for each location.

- The number of units produced allocates overhead costs based on the number of units manufactured.

- The predetermined overhead rate is also commonly called predetermined absorption rate or predetermined overhead absorption rate.

- One approach is to calculate separate PORs for each product line or production process, based on the most relevant allocation base.

- This foresight is invaluable for competitive bidding, seasonal pricing, or launching new products without risking underpricing.

- Remember, even a rough predetermined rate is better than ignoring overhead entirely, which is a common mistake that leads to underpricing and cash flow problems.

By having multiple rates like this, you can achieve a greater degree of accuracy. The downside is that it increases the amount of accounting labor and is therefore more expensive. Another tremendous advantage for companies using the predetermined overhead rate is it provides a more consistent analysis even during periods of season variability.

Despite what business gurus say online, “overhead” and “all business costs” are not synonymous. That’s the entire idea—by estimating the amount of overhead that will be incurred, you can better plan for and control these costs. If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm. Dinosaur Vinyl uses the expenses from the prior two years to estimate the overhead for the upcoming year to be $250,000, as shown in Figure 8.38. Learn about emerging trends and how staffing agencies can help you secure top accounting jobs of the future.

Accurate calculation of the predetermined overhead rate is paramount for effective cost management and profitability analysis. Additionally, this rate serves as a benchmark against which actual overhead costs can be compared, allowing businesses to identify areas for cost optimization and improve overall efficiency. In simple terms, it’s Suspense Account a kind of allocation rate that is used for estimated costs of manufacturing over a given period. It’s a good way to close your books quickly, since you don’t have to compile actual manufacturing overhead costs when you get to the end of the period. Keep reading to learn about how to find the predetermined overhead rate and what this means.

Sales and production decisions based on this rate could be faulty

The most prominent concern of this rate is that it is not realistic being that it is based on estimates. Since the numerator and denominator of the POHR formula are comprised of estimates, there is a cash flow possibility that the result will not be close to the actual overhead rate. The fact is production has not taken place and is completely based on previous accounting records or forecasts. The choice of selecting any absorption basis depends on the judgment and common sense; especially depends on the type of the manufacturing activities.

- If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be under applied by 75 (1,500 – 1,575) as shown in the table below.

- Big businesses may actually use different predetermined overhead rates in different production departments, as these may vary significantly.

- The overhead rate is calculated by dividing the total overhead costs by the total activity base.

- Moreover, predetermined overhead cost rates enhance budgetary control and financial planning by providing a clear framework for managing overhead expenses.

- In your furniture company, let’s say you expect to use 20,000 machine hours this year.

The production manager has told us that the manufacturing overhead will be $ 500,000 for the whole year and the company expected to spend 20,000 hours on direct labor. The management concern about how to find a predetermined overhead rate for costing. Various activity and cost bases can be used, including direct labor hours, machine hours, and production units. The choice of activity base depends on the nature of the overhead costs and the production process. The application rate that will be used in a coming period, such as the next year, is often estimated months before the actual overhead costs are experienced. Often, the actual overhead costs experienced in the coming period are higher or lower than those budgeted when the estimated overhead rate or rates were determined.